About

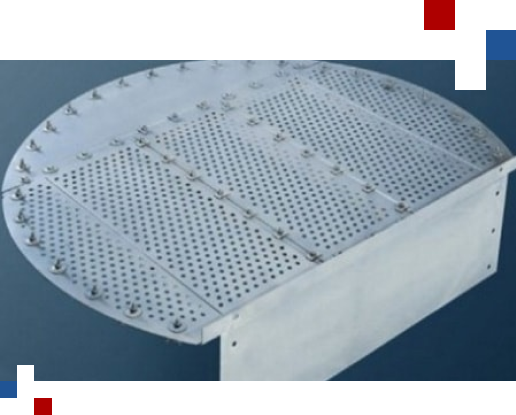

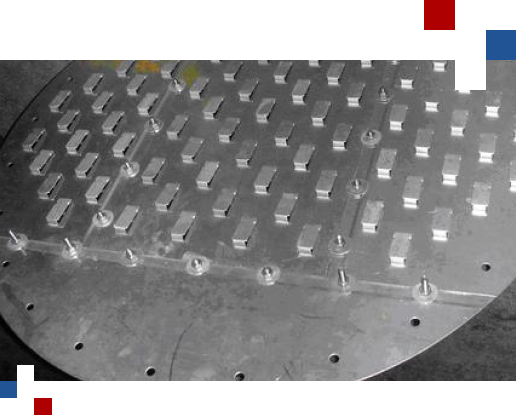

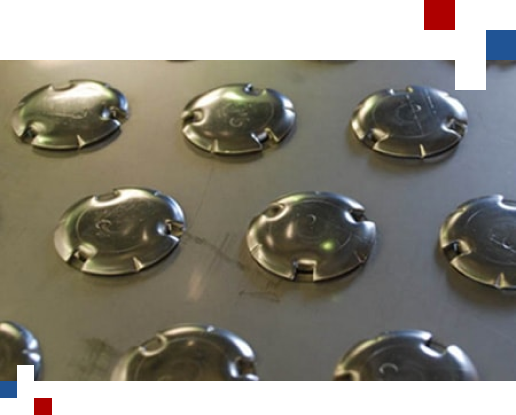

CHSP Sieve Trays

A perforated plate with holes is a sieve tray. At the same vapor velocity, a sieve tray has a higher entrainment than a valve tray. Its minimal capacity is at about 70%. They are inexpensive when a low turndown is not necessary. Comparing sieve trays to bubble caps and valve-type trays, they are both more affordable and simpler in design.

Operation, maintenance, and cleaning of sieve trays is relatively easy. In comparison to the other trays, the pressure drop across the sieve trays is lower.