. About

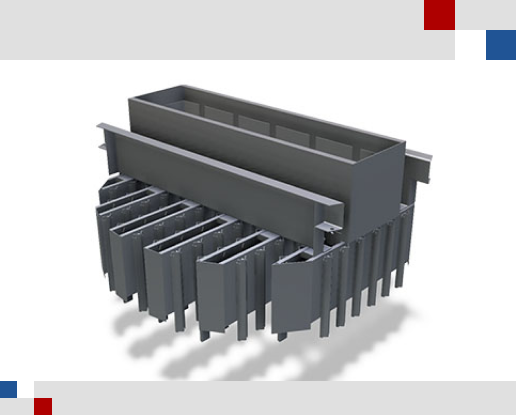

CHSP Channel Type Distributor

Distributors of the channel type are one of the most liquid distributors. For structured

packing, they work particularly well. Up to 1500 mm column diameter can be accommodated

using this. Both a single piece and segmented versions of it are available.

Due to the liquid’s channelized design, the packing’s maximal cross-section is covered, and

the liquid is distributed uniformly. due to the evenly distributed vapor flow, also has a low-pressure drop. Both drip tubes and bottom holes can be included with the distributor. Wherever the possibility of fouling exists, drip tubes may be used.