. About

CHSP Pall Rings

The most popular type of random packing.

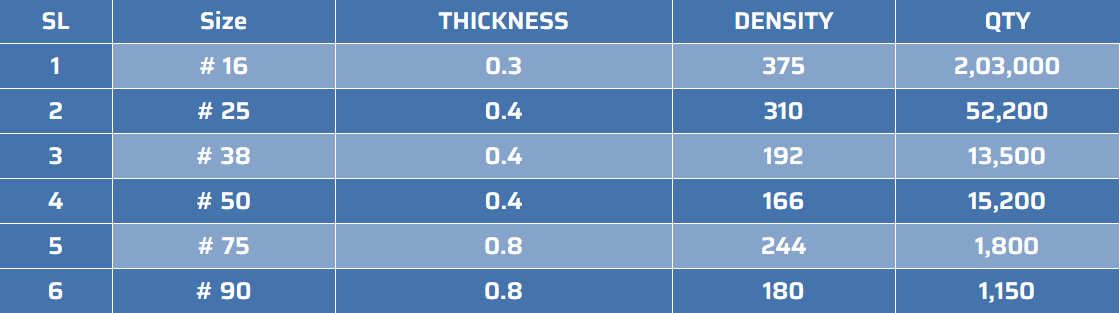

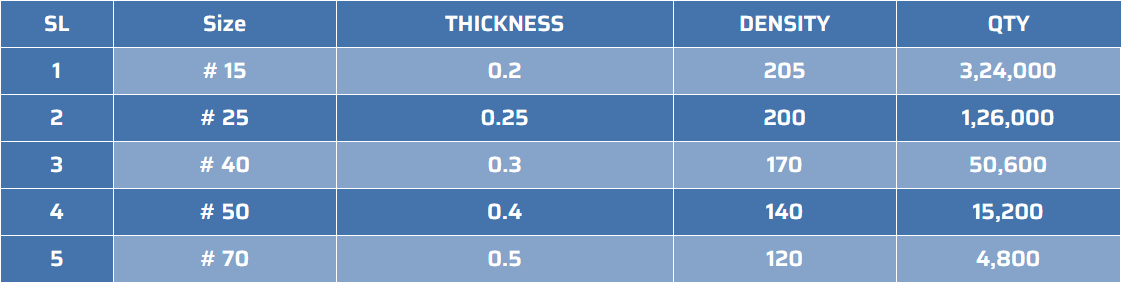

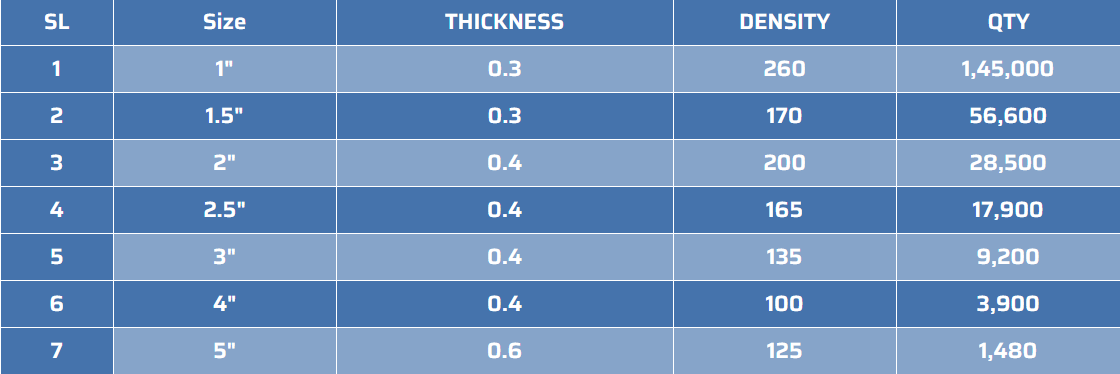

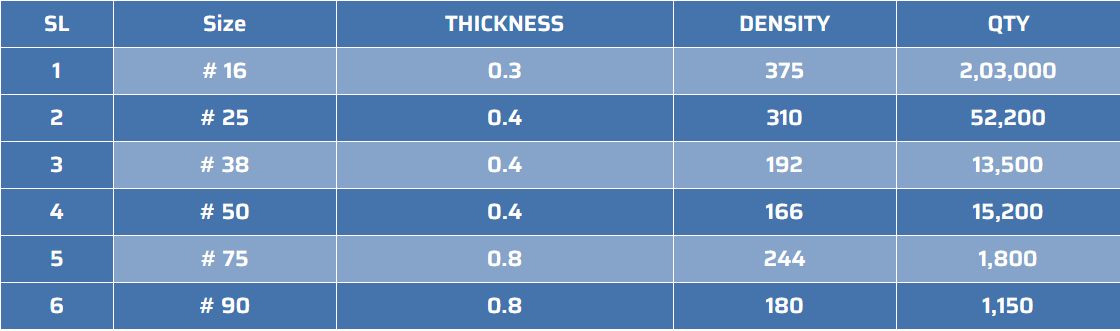

Random packing greatly improved with the invention of Pall Rings. By creating internal drip points by piercing tabs into the ring’s wall, it was able to outperform Raschig Ring Packing in terms of capacity and efficiency by 50% to 80%.

Pall Rings are distinguished by having the same height as their diameter, much like the Raschig Ring Packing. Pall Rings are frequently employed in the distillation and absorption processes. Pall rings are more productive, have less pressure drop, offer more operational flexibility, and are more effective. They come in metal and plastic varieties.

ging is CHSP Sheet Metal Structured Packing. The packaging has a lot of benefits including excellent mass-transfer efficiency.

MOC

- SS316L, SS304, (PP, PVDF, PTFE), Alloy, Steel, Hast alloy, Duplex Incloy, Monel, etc.