About

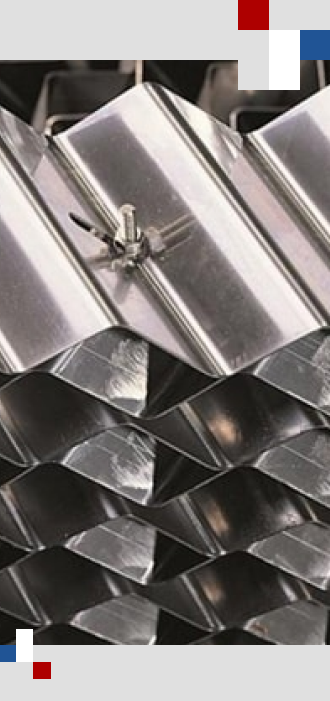

CHSP Sheet Metal Packings

The most popular type of structured packaging is CHSP Sheet Metal Packing. The packaging has a lot of benefits including excellent mass-transfer efficiency.

In comparison to random packing of the same capacity, sheet metal packing provides a larger surface area per cubic meter. Each packing component is composed of several vertical corrugated layers with/without perforations. Within the element, the gas or liquid is dispersed and disseminated radially from layer to layer. The sheet metal’s surface texturing improves wettability and mass transfer even more when these components are installed as per standard installation procedure.

Features

- Due to shorter columns, its high mass transfer surface area makes it appropriate for close boiling component distillation.

- Its organised design ensures that there is no liquid channelling and just a minimal amount of liquid redistribution is needed.

- It is a good choice for vacuum distillation systems due to its extremely low-pressure drop.

- Comparatively speaking to random packing and trays, it has a higher vapor load capacity.

- Low liquid hold-up is offered.

Application

- Atmospheric and Vacuum Columns in a refinery

- Petrochemical Columns

- Stripping Columns

- High pressure and atmospheric pressure columns

- Distillation & Extraction processes